Modern mobile computing devices demand exponential power growth, paralleling Moore’s Law in transistor density. However, energy storage has historically lagged behind. Xiaomi addresses this critical bottleneck with its revolutionary Jinshajiang battery technology and the intelligent MiPPS charging protocol. Going from conventional graphite to silicon-carbon anodes, Xiaomi strikes a balance between achieving high energy density without sacrificing longevity. This report analyzes how both the Xiaomi 15 and Xiaomi 14 Ultra leverage these innovations in order to mitigate the thermodynamic risks commonly found in ultra-fast charging speeds.

The Electrochemical Shift: From Graphite Limits to Silicon Revolution

Since commercialization in 1991, graphite has represented the industrial standard due to its structural stability. However, the increasing power consumption of modern smartphones, together with demands for thinner form factors, has pushed graphite to its theoretical capacity limits. Xiaomi’s Jinshajiang technology represents the necessary transition to a silicon-based architecture that can transcend these physical constraints.

While traditional graphite anodes are limited to a specific capacity of about 372 mAh/g, silicon forms an alloy with lithium, theoretically achieving 4200 mAh/g. Xiaomi’s latest flagships employ a Silicon-Carbon composite structure. Teardown analysis reveals that cells present in devices such as the Xiaomi 14 Ultra have about 6% silicon content. This propels the energy density to a class-leading 779 Wh/L. The more extreme implementation can be found on the ultra-thin magnetic power bank, where the silicon content tops out at 16%, allowing 5000mAh to be fitted within a 6mm thick chassis.

Engineering Solutions for Volume Expansion

Volume Expansion. This massive energy density advantage of silicon comes with a significant mechanical drawback. Where graphite expands about 7-10% upon charging, silicon particles can expand up to 300%. Left unchecked, this results in particle pulverization, loss of electrical contact, and destruction of the SEI layer. Xiaomi employs a multi-layered engineering strategy to neutralize these risks.

Laser-Patterned Energy Channels

In an effort to control physical stress, Xiaomi employs microscopic engineering at the electrode level. Dubbed “Energy Groove” technology, it involves creating 2,376 micro-channels on the surface of the electrode by laser patterning. The channels perform a twofold function: they act as a mechanical buffer zone, in which silicon particles expand without deforming the pouch of the battery, while they function as ion highways, increasing infiltration by the electrolyte to lower internal resistance during high-speed charging.

Bionic Self-Healing Electrolyte

Beyond mechanical solutions, Xiaomi guarantees chemical stability due to a “bionic self-healing barrier.” Unlike the rigid traditional SEI layers that crack under silicon expansion, the polymer-infused layer of Xiaomi exhibits high ductility. Similar to human skin, it can repair the micro-cracks formed during charging cycles. This mechanism avoids electrolyte dry-out and absorbs chemical stress induced by HyperCharge technology.

MiPPS and HyperCharge: Thermodynamic Control

Hardware alone cannot prevent thermal damage due to fast charging. It is all about managing the electrical parameters with utmost precision, namely voltage and current. This is where the Xiaomi HyperCharge architecture and the MiPPS protocol rewrite safety standards.

From PD to MiPPS – the Evolution

Traditional USB Power Delivery protocols only allow fixed voltage profiles; for example, 9V or 15V, which forces the phone to step down the voltage internally and generates excessive heat. MiPPS, or Xiaomi Programmable Power Supply, enables highly granular voltage control with steps as small as 20mV. This allows “Direct Charging,” where the adapter supplies the exact voltage required by the battery, effectively moving the heat source from the phone to the wall adapter.

Dual Charge Pump Architecture

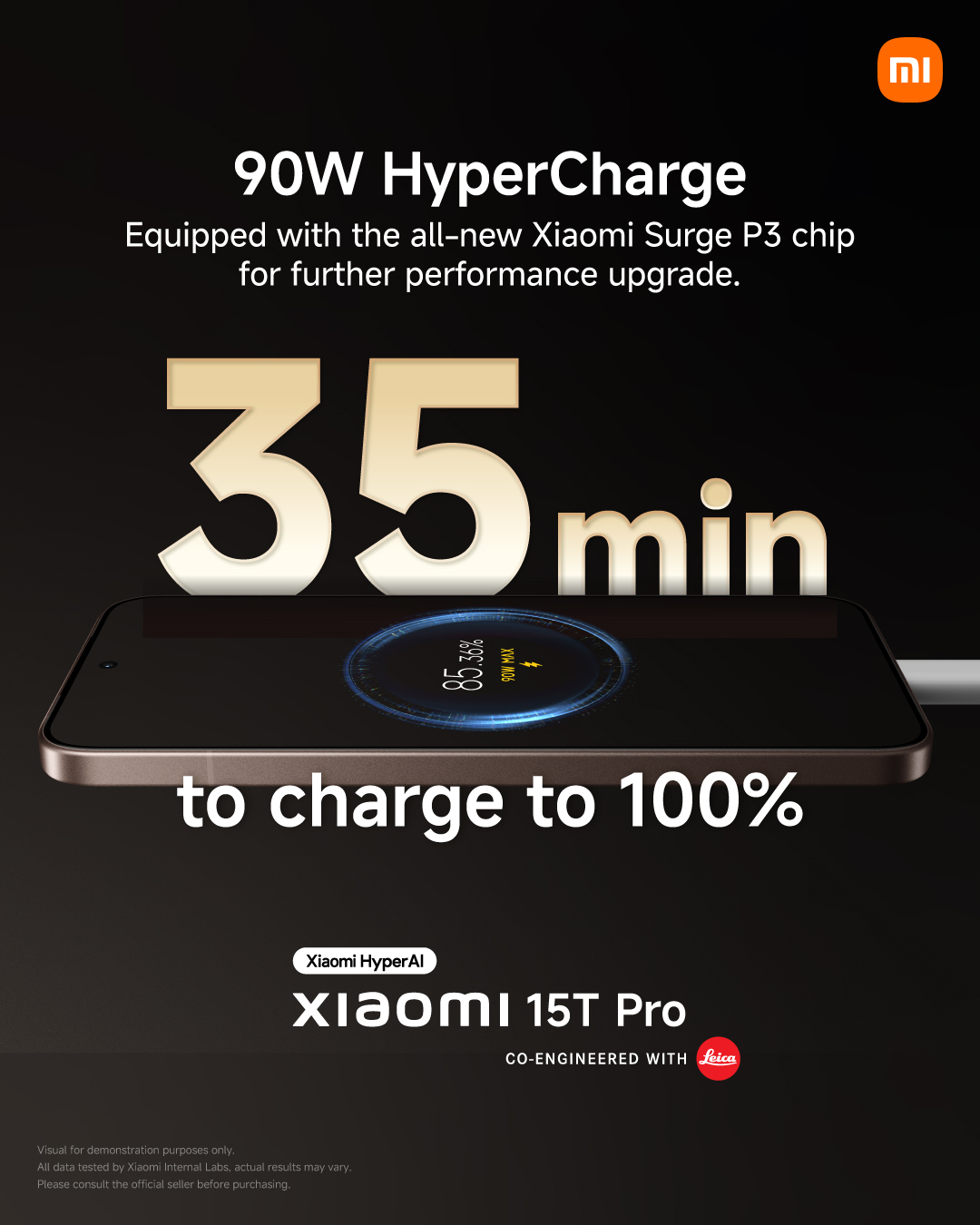

To ensure safe speeds of 90W and 120W, Xiaomi employed a Dual Charge Pump architecture, powered by Surge P1 and Surge P3 chips, respectively. These chips split the incoming current and convert voltage at an ultra-high efficiency of 96.8%. Instead of wasting energy as heat, as traditional circuits do, the Surge chips employ minimal thermal loss, preventing the battery from “cooking” during the charging process.

The Surge Chipset Ecosystem: Active Safety Management

One key differentiator in Xiaomi’s strategy is in offloading battery management from the main Snapdragon 8 Elite processor onto dedicated custom silicon. The Surge G1 battery management chip is the brain of this operation, enabling real-time millisecond-level voltage and temperature monitoring. The Surge G1 chip performs dynamic SOA analysis. In case the ambient temperature is higher than expected, or if the battery is showing signs of aging, the chip intelligently reduces the charge rate. Its ISP capability can even detect micro changes in internal chemistry due to drops or impacts and prevent thermal runaway before it starts.

The 1600 Cycle Standard: Real-World Durability

Does this tech actually work in the real world? The industry benchmark holds that a battery is “healthy” when it still retains 80% of its capacity after 800 cycles. Xiaomi, however, guarantees that its Jinshajiang batteries will retain 80% of capacity after 1600 cycles. This effectively doubles the lifespan of the battery compared to competitors. User feedback and independent tests confirm that despite using silicon and 90W+ charging speeds, degradation rates remain minimal. Paired with the IceLoop* cooling system, which separates vapor and liquid channels to improve thermal efficiency by 100%, Xiaomi has successfully proven that fast charging does not need to damage battery health.

Emir Bardakçı

Emir Bardakçı